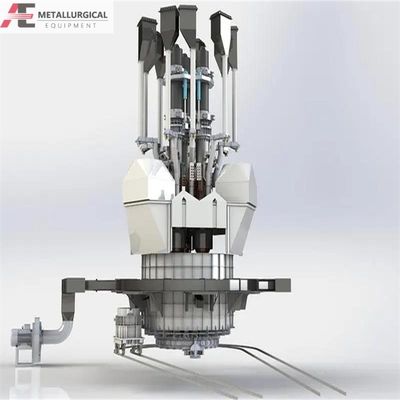

Ferromanganese furnace

Ferro-manganese Submerged Arc Furnace---Structure characteristics

Ferro-manganese submerged arc furnace is a kind of industrial furnace which consumes much power. Full set equipment mainly consists of furnace shell, fume hoods, lining, short net, cooling system, exhaust system, de-dusting system, electrode shell, electrode lifting system, loading and unloading system, electrode holder, arc burner, hydraulic systems, submerged arc furnace transformer and various of electrical equipments.

Ferro-manganese submerged arc furnace equipment is divided into three layer arrangement

The 1st layer is furnace body (including furnace bottom support, furnace shell, furnace lining), tapping system (including the ladle and ladle car.), arc burner etc.

The 2nd layer

1, Fume hood: At present, mostly of submerged arc furnace adopts closed or semi-closed low hood structure, with the characteristics of environmental protection, facilitate maintenance and improve the operation environment. The closed structure can also collect the exhaust gas (main ingredient is carbon monoxide) which is generated in the production and used in synthetically. Also can reduce the heat loss of the circuit, decrease the temperature of the electrode, and improve the operating environment.

2, Electrode holder: Most of submerged arc furnace with three-phase power supply. Electrode in triangle or inverted triangle, symmetrical position placed in the middle of furnace chamber. Large submerged arc furnace generally adopts anthracite, coke and coal tar pitch mixed as electrode material, in the process of smelting , it roasting by itself as electrode.

3, Short net

4, Copper tile

5, Electrode shell

6, Unloading system

7, Stoking machine

8, Fume exhaust system

9, Water-cooling system

10, Submerged arc furnace transformer

11, Operating system

The 3rd layer

1, Hydraulic system

2, Electrode press and release device

3, Electrode lifting system

4, Steel platform

5, Hopper and cycle material distribution car

Other additional: skew Bridge feeding system, electronic batching system, etc.

Specification of Ferro Manganese (High Carbon)

|

Specification of Ferro Manganese (High Carbon)

|

|

Contents

|

Min (%)

|

Max. (%)

|

|

Manganese (Mn)

|

74

|

82

|

|

Carbon (C)

|

|

7.5

|

|

Silicon (Si)

|

|

1.2

|

|

Phosphorouse (Phos)

|

|

0.350.05

|

|

Sulphur (S)

|

|

|

|

Specification of Ferro Manganese (Medium Carbon)

|

|

Contents

|

Min (%)

|

Max. (%)

|

|

Manganese (Mn)

|

74

|

82

|

|

Carbon (C)

|

|

7.5

|

|

Silicon (Si)

|

|

1.2

|

|

Phosphorouse (Phos)

|

|

0.350.05

|

|

Sulphur (S)

|

|

|

|

Specification of Ferro Manganese (Low Carbon)

|

|

Contents

|

Min (%)

|

Max. (%)

|

|

Manganese (Mn)

|

74

|

82

|

|

Carbon (C)

|

|

7.5

|

|

Silicon (Si)

|

|

1.2

|

|

Phosphorouse (Phos)

|

|

0.350.05

|

|

Sulphur (S)

|

|

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!